The 3 Types of Supply Chains for IT OEMs Explained

Flexible Logistics and Inventory Management Solutions Built for the Future

There are many types of supply chains, but with inventory, transportation and labor often being some of the most significant cost drivers for original equipment manufacturers (OEMs), there are key features to consider when selecting a supply chain model. And with greater pressures to reduce expenses, create efficiency, improve visibility and exceed customer expectations, it’s more important than ever to enhance your end-to-end supply chain and logistics processes, too.

Meet your customers in the global marketplace by optimizing your supply chain with a flexible solution built to your needs — without sacrificing your customer experience.

Which type of supply chain model is best for your business and customers?

1Supply Chain Challenges

How can OEMs manage logistics, customer service, technology operations and full product lifecycle services simultaneously while also maintaining a consistent customer experience?

2Looking Ahead

From the pandemic to digital transformation and sustainability, it's safe to say expectations across the board are changing. What does the IT supply chain look like moving forward?

33PL Model

In a third-party logistics (3PL) model, the provider essentially serves as a department of your company and manages the complete supply chain. Why consider a 3PL partner for your global supply chain?

4Fulfillment Model

A fulfillment model is built on a relationship focused on fulfillment compared to the more comprehensive nature of the 3PL model. What’s the difference between this and a standard distribution model?

5Hybrid Model

The hybrid model allows you to scale and shape your supply chain as your go-to-market strategies and customers' buying patterns shift over time. What are the main benefits of this type of supply chain model?

6The Missing Link in Your Supply Chain

A logistics partner can support many types of supply chain models — 3PL, fulfillment, hybrid and more — enabling you to more easily tackle the post-pandemic marketplace.

Supply Chain Challenges

One key consideration when rethinking your go-to-market strategy and serving customers in the global marketplace is whether you’re utilizing the optimal types of supply chains to position your strategy for success.

Over the past several years, supply chains have been stressed like never before, and the trending outlook is for ongoing disruption and rising costs. At the same time that these challenges have skyrocketed, the supply chain has never been more critical to serving your customers, supporting both your products and service lines and positioning your business for growth.

Managing logistics, fulfillment, customer service and support, technology operations and full product lifecycle services are significant elements of today’s complex technology supply chains. Many technology companies are making the shift to an everything-as-a-service (XaaS) business model to support their digital transformation journey as well as those of their customers. Perhaps your organization is moving to a software-centric business model and deemphasizing hardware in the future. Or maybe you need to transform your integration and logistics footprint to deliver solutions to customers faster. Or maybe your organization is facing fulfillment issues as well as a desire for improved business efficiency. But ongoing challenges such as staffing, transportation, logistics delays and rising operating and capital expenses are a fact of life moving forward.

The question then becomes, how can IT original equipment manufacturers (OEMs) overcome these challenges while simultaneously maintaining a consistent, seamless customer experience?

The answer is twofold.

First, you need to choose the best type of supply chain model to support your business goals with lower costs, better performance and improved customer satisfaction. With the right type of supply chain model in place, you can better position your company to meet customer expectations and global demands. Second, while each organization faces its own unique headwinds, outsourcing your supply chain management to a trusted technology partner with flexible supply chain models can help you navigate the increasingly volatile supply chain environment.

Supply Chain Management: Looking Ahead

The overall state of global supply chains prior to the COVID-19 pandemic was unpredictable at best due to political instability, logistics disruptions, rising fuel costs and other factors. The pandemic exacerbated those issues with shutdowns and upheavals around the globe. As companies and consumers scrambled to cope, the supply chain underwent a massive shift in remote working, cloud computing and e-commerce.

All types of industries, including retail, homewares and manufacturing, are still reeling from the impact of the pandemic. Today, few industries operate in the exact same market and supplier base as they did in 2019. In a recent survey, 60% of technology executives said the pandemic changed the way they work for the long term. In response to the pandemic, 70% of executives said they created new digital business models and revenue streams. Even as companies adapt the way they do business to fit the post-pandemic marketplace, they must at the same time maintain and manage existing customer relationships and expectations to maximize both customer satisfaction and retention.

As society and the world economy have reopened, one of the lessons businesses learned was the need to build a more fault-tolerant supply chain. Many IT OEMs uncovered inefficiencies, a lack of visibility and unsustainable business practices during the global disruption. As suppliers of products and services closed, it became apparent that there were many single points of failure forcing manufacturers to reduce outputs or close production entirely.

One of the leading responses to the pandemic was — and continues to be — accelerated digital transformation for IT OEMs and their customers, as companies must adapt quickly to meet growing customer demands and expectations. While the types of digital transformation vary, the common goal is to transform an organization’s processes and culture to take advantage of technology to deliver more value to customers who have evolving expectations for how they consume technology products and services.

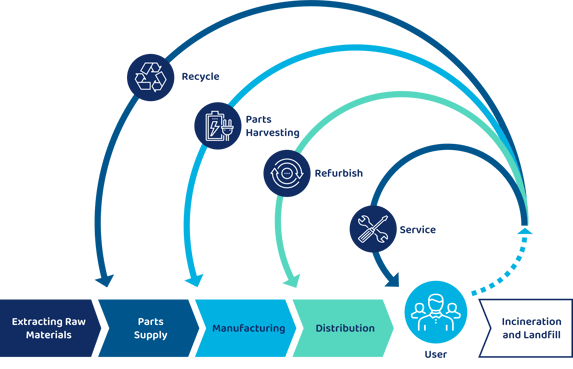

Meanwhile, IT OEMs face increasing expectations for ethical supply chain management, too, including developing a sustainable circular economy strategy to minimize their social and environmental impact while maximizing product lifetime value.

Factors such as carbon emissions, waste products and sourcing from potentially problematic suppliers represent inefficiencies in the supply chain. The goal of the circular economy is to design waste and pollution out of the global supply chain. Collaborative efforts to tackle ethics in supply chain management help deliver results in business performance and corporate social responsibility and are the best way to drive positive, long-lasting impacts for the environment.

Factors such as carbon emissions, waste products and sourcing from potentially problematic suppliers represent inefficiencies in the supply chain. The goal of the circular economy is to design waste and pollution out of the global supply chain. Collaborative efforts to tackle ethics in supply chain management help deliver results in business performance and corporate social responsibility and are the best way to drive positive, long-lasting impacts for the environment.

As production resumes full capacity, supply chain management leaders understand the need for diversified sourcing, deeper visibility and other supply chain strategies. They know that as they evolve their business models for the post-pandemic world, their supply chains must keep pace with change to provide the agility and resilience that can turn supply chain management into a competitive advantage.

The Benefits of Outsourcing Supply Chain Management

As supply chain costs and complexities continue to expand, IT OEMs are turning to outsourced logistics partners to take advantage of expertise, best practices and technologies. Outsourcing supply chain management services delivers a range of benefits for your organization and your customers, including:

- Cost savings and revenue growth opportunities

- Access to supply chain experts

- Fewer operational and/or legacy burdens

- More freedom to focus on strategy

- Flexibility and scalability

- Expanded customer base and reach

- Increased inventory velocity

- Improved customer satisfaction and time to market

- Enhanced competitive advantages

With the right outsourcing partner, you can uphold your commitment to customers at a lower cost while also pivoting to a renewed focus on your key business drivers and initiatives. When outsourcing your supply chain, it’s essential to understand the different types of common supply chain models in the IT market. The best fit will depend on your business strategy and expectations, so aligning with an experienced supply chain partner can help guide you through the process.

The 3 Types of Supply Chains Explained: 3PL Model

In the third-party logistics (3PL) model, the provider essentially serves as a department of your company and manages the complete supply chain, including order taking, warehousing, inbound and outbound logistics, credit and collections and more. By working collaboratively, the 3PL model provides a consistent customer experience and delivers accelerated cash-cycle times and superior order-cycle times while your organization maintains control of pricing and direct sales relationships.

Defining the 3PL Model

*Tech Data Global Lifecycle Management (GLM) is now Shyft Global Services

3PL Supply Chain Model Case Study

Leading electronics OEM Sharp Electronics engaged a 3PL model and outsourcing partnership to improve shipping lead times and reliability, shipment visibility and order tracking. The 3PL model reduced duplication of fulfillment services, expanded the warehouse footprint and improved order status and tracking. In addition to streamlining its supply chain and being able to more efficiently prioritize its core initiatives, Sharp was recognized for distribution and product line performance improvements.

The 3 Types of Supply Chains Explained: Fulfillment Model

Increased direct-to-customer demand and the need for agility in serving B2B buyers have transformed how technology companies approach fulfillment services. This supply chain model is built on a relationship focused on fulfillment compared to the more comprehensive nature of the 3PL model. Nonetheless, a logistics services provider can manage distribution to consumers, channel partners and resellers as needed, integrating into your existing operations to increase efficiency. A fulfillment partner can take charge of your end-to-end inventory management, with collaborative forecasting and replenishment processes.

Additionally, outsourcing pre- and post-sales customer interactions to a partner who can act as an agnostic, white-label extension of your team supports end-user satisfaction. The right partner has transportation and logistics capabilities to overcome customs and border issues as well as the required infrastructure in key locations, so inventory consolidation and improved stock and parts availability help build customer satisfaction, too.

Defining the Fulfillment Model

*Tech Data Global Lifecycle Management (GLM) is now Shyft Global Services

Fulfillment Supply Chain Model Case Study

A mobile device OEM was challenged to support three generations of devices in a large geographic region with multiple partners and limited visibility into part inventory to support day-to-day business operations. They chose to leverage a single source fulfillment partner who developed an online portal to place orders for parts and consolidated inventory into regional stocking points to shorten transportation lead times. This helped to reduce delivery time, improve availability and streamline customs clearance procedures.

The 3 Types of Supply Chains Explained: Hybrid Model

Outsourced logistics providers can adapt their models to your organization’s requirements. The hybrid model allows you to scale and shape your supply chain as market strategies and customer buying patterns shift over time, similar to an omnichannel go-to-market strategy. A hybrid model supports single-pool inventory management, inventory optimization and an agile supply chain, blending in-house expertise and external production, distribution and after-sales support.

In a hybrid supply chain model relationship, the logistics partner assumes the role you want them to have. For example, you could handle e-commerce fulfillment in-house for one product line and rely on your outsourced partner for other products. Or you may prefer to manage orders for Tier 1 customers in a 3PL relationship and serve Tier 2 and 3 orders through fulfillment centers. With a hybrid model, you can structure your supply chain to meet your customers’ needs and ensure supply chain success.

Defining the Hybrid Model

*Tech Data Global Lifecycle Management (GLM) is now Shyft Global Services

Hybrid Supply Chain Model Case Study

A leading manufacturer of imaging and information products for businesses and end consumers faced a period of stagnant growth and increasingly competitive product innovation pressures, which led the company to evaluate all aspects of its business, including its supply chain and route-to-market processes. After a thorough vetting process, the company selected a services partner who could implement a hybrid operating model to address, improve and modernize four key business areas related to its supply chain, including cost controls, lead time delays, processing complexity and dealer service levels and experience.

In this hybrid supply chain model relationship, the partner serves as a single managed-service provider for all logistics activities as well as product planning, order management, credit, invoicing and collections for fulfillment customers. The partner also assumed IT development needed to support business needs and dealer experience. The reduction in administrative overhead enabled the company to focus more on selling and less on transactional tasks.

The Missing Link in Your Supply Chain

See how companies like yours build superior customer relationships by outsourcing some or all of their supply chain operations to free up resources and improve cash flow through inventory position optimization. A trusted global logistics partner like Shyft Global Services supports all types of supply chain models covered above, enabling your organization to outsource services and more easily tackle the challenges of the post-pandemic marketplace. Shyft’s supply chain experts can help identify the supply chain model that works best for your business while also providing your customers increased visibility into order processing and a seamless customer experience.

Accelerate your transformation with an outsourced supply chain partner while ensuring your customers receive the high level of service quality they have come to expect from your organization. Discover how companies from different industries around the globe have successfully outsourced supply chain management services to revitalize their operations, focus on business transformation and drive better outcomes.