Expert Depot Repair Services

Comprehensive Global Logistics and Circular Economy Support

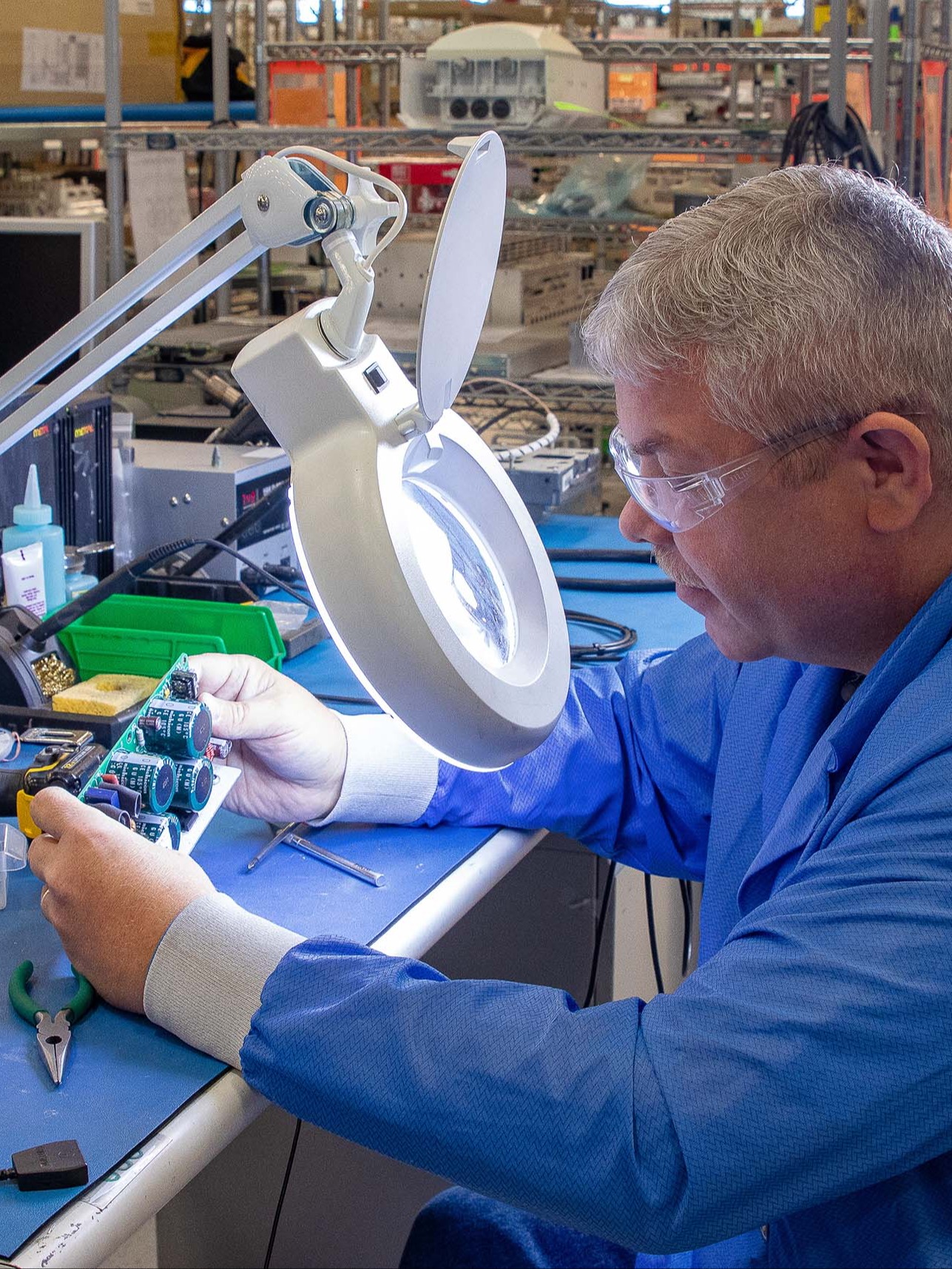

Maintain customer loyalty and reduce costs through a scalable repair service that’s responsive, agile and flexible — all delivered by expert engineers and trained technicians.

Complete Control With Depot Repair Services You Can Trust

Shyft Global Services’ comprehensive depot repair services and global depot repair centers cover the full spectrum of products, from data center to client to specialty embedded technology — and more.

Customer Confidence

Your customers can trust that their hardware will be repaired quickly and with the quality they deserve.

Diagnostic Experience

Our experience across data center, client and OEM-specific technologies help you provide upgrades sooner.

Quality Control

Together, our quality management system and technology expertise deliver world-class quality every time.

Logistics Consolidation

Consolidate your end-to-end logistics processes and provide a seamless experience with our global facilities.

Streamlining Your Global Repair Service Operations

With a single global depot repair services partner, your technology goes further. Shyft provides comprehensive technology repair services and sustainable solutions across various industries and verticals, allowing your technology to stay in the hands of your customers — longer.

Depot Repair Service Capabilities

-

Depot Repair Service Capabilities

Repair

The speed and ease of product repair greatly impacts customer satisfaction and loyalty. Fortunately, speed and quality go hand in hand for our technical engineers who work to keep your products in your customers’ hands working as intended. With Shyft’s comprehensive repair depot services, your customers stay up and running. Our capabilities include:

- Reverse engineering

- Test fixture development and programming through automation

- NTF screening and data erasure

- Component-level repair at the system and FRU levels

- Ball-grid array (BGA) and fine-pitch device replacement

- Product upgrades and ECO management

- Root cause analysis

- Cosmetic-specification compliance

Program Management and Reporting

Your Shyft program manager serves as your key point of contact and handles all your depot repair management needs, reducing complexity so you can focus on mission-critical tasks. Our in-house reporting tool offers constant access, giving you visibility into your depot repair services and global logistics operations anywhere, anytime. With Shyft, you also gain enhanced:

- SLA/KPI reporting

- Web portal access

- Repair history and analytics

- Inventory visibility

- Customer ERP connectivity

- Shipment tracking

Depot Inventory Management

Recapture value in a circular economy and optimize your global logistics processes by taking advantage of our flexible supply chain models, inventory management systems, outbound logistics and supply chain management expertise. Easily track inventory at each stage of the product lifecycle with reporting tools that help support:

- Spare parts planning and stocking-level maintenance

- Flexible supply chain modeling, including advanced exchange and configuration to order

- Forward stocking locations

- OEM/ODM returns management

- Compliant e-cycling

Demonstration and Evaluation

In addition to comprehensive depot repair services, Shyft offers in-depot demo/evaluation equipment configuration and deployment programs. Our systems and tools help enable new product sales by delivering a seamless experience that delights your customers and keeps your brand top of mind. Demonstration and evaluation capabilities include:

- Integration and collaboration with customers, sales and order management

- Contract administration

- Inventory management and warehousing

- Asset tracking, reporting and notifications

- Packaging and logistics development and support

- Asset installation and de-installation

Rethink Your Depot Repair Services Strategy

Shyft’s depot repair services keep your customers up and running with minimal downtime, helping to maintain customer satisfaction and productivity while reducing costs. Although some technology failure is inevitable, an efficient repair process and a team of expert engineers from a leading repair company can help keep your customers functioning at optimal levels.

Best Practices Through an Unbiased Approach

Shyft's skilled engineers and trained technicians work on electronics based on past and present architectures, including the world's most advanced computing, networking, storage, and I/O — down to the board component level, setting us apart from other depot repair companies. We have expert technicians available to test, repair and analyze nearly any type of technology, and our unbiased approach ensures accurate, actionable information.

-

Shyft engineers are skilled experts in failure data and root cause analysis. First, we determine if the asset can be repaired quickly and efficiently. After deep testing to determine root cause, our unbiased observations and analyses provide invaluable feedback to help you make informed decisions about when it’s time to upgrade or update technology — so you can improve design, reduce costs and provide your customers the highest-quality product.

-

Shyft practices a secure and environmentally friendly scrap process, managing obsolete and excess field repair units (FRUs) of components, including field purges. We deliver NIST- and DoD-compliant data destruction and sanitization services. Each solution is custom-engineered to fit your customer's environment, ensuring all data is eradicated in the most efficient manner possible — all while protecting the future through environmentally responsible practices.

-

Unprecedented market conditions can put a strain on medical device supply chains. Shyft has high-tech integration labs and equipment testing facilities that are ISO 13485 compliant and maintain the level of strict controls unique to the requirements of healthcare technology manufacturing.

-

Sixty-two percent of cable provider customers want fewer outages and further improvements to service reliability and quality. Providing the right solutions quickly is a critical component to your customer’s experience, and with more than two decades of experience serving multiple-system operators, Shyft offers the broadband solutions to help.

-

Our Quality, Environment, Health and Safety (QEHS) system has been continually developed, maintained and improved for over three decades. Our facilities are individually certified and managed with overlapping key process and coordination between locations. We built our business to support yours, and our practices are compliant with numerous industry standards, including:

- ISO 9001:2015 Quality Management Systems

- ISO 14001:2015 Environmental Management Systems

- ISO 13485:2016 Medical Devices

-

The Shyft team is skilled at reverse engineering and repairing at the component level — including the rework or replacement of delicate ball-grid array (BGA) and fine-pitch devices. This expertise reduces service costs and improves repair yields while extending the service life of legacy products. We follow the 5S principles of operational excellence, implementing mature, lean and continuous improvements while applying industry standards to local operations.

Quality Repairs and Responsive Services

Product repairs are a key driver of customer experience — and your customers deserve prompt, efficient responses. Our industry-leading repair services team is there when equipment needs to be repaired or updated, and quickly finds the right solutions to ensure overall satisfaction and long-term retention.

-

Shyft’s New Program Implementation (NPI) process takes a collaborative approach when repairing your products for customers. We assign a dedicated NPI manager and team to co-create a project plan that works best for you. Our team of experts coordinates the onboarding process, tracking, reporting, document management and instructions — ultimately giving your customers a seamless repair experience.

-

Our technicians and engineers work with you at a program level to understand what success looks like for your organization. Based on time-tested best practices and methods, we work with you to establish KPIs and SLAs that match your quality standards, and our metrics and analytics reports are available to you 24/7.

-

As your offerings evolve, we evolve with you. From onboarding new products to end-of-lifecycle management, we stay in lockstep with your product roadmap and support requirements — even well past a product’s useful life when necessary — to help maximize the lifetime value of your products.

Improved Line of Sight Into Your Equipment

Shyft regularly gathers and reviews operational data to have an open dialogue with you about your products. We analyze repair data to look for trends, such as an increase in the number of product repairs, to help proactively identify possible causes and solutions. We also offer product-specific root cause analysis services for deeper technical analysis.

-

PRISM is our internally developed, proprietary shop floor control system for managing global logistics and depot repair services operations globally. It collects data and provides reports through a single, personalized portal for program managers and customers to review tracking/tracing of serial numbers, repair history, shipment tracking, quality assurance activity, quality data and much more. Key benefits of PRISM include:

- Having the right information at the right time (24x7, globally)

- Flexible and custom development add-ons

- Better inventory visibility

- Central repository of data to manage business across multiple locations

- Data-driven planning for inventory replenishment

-

Shyft routinely works to refine and optimize test automation codes, providing the technical expertise needed to amend or edit code to improve products or bring them back online. Our device troubleshooting ensures thorough testing and proper repairs, and we offer custom test fixture creation for solid troubleshooting, as well as customer support and manufacturing feedback.

More Services to Meet Your Customers’ Needs

Expand your market reach, increase capacity, reduce operational costs and accelerate time to market by combining services under a single provider who can cover all your global logistics processes, depot repair services and more. From design to disposal, you can integrate component procurement, offer onsite professional services and provide a range of technical assistance, maintenance and IT asset disposition services.

-

Shyft’s logistics centers help you modernize your logistics network and generate long-term success for both you and your customers. Take advantage of our inventory management, delivery and supply chain logistics to save your organization time and money while reducing risk. Your products are securely transported and tracked, giving you full visibility every step of the way. Our global footprint and forward stocking locations allow us to keep inventory near your customers anywhere in the world.

-

Optimize the way you manage your product lifecycle with industry-standard technology services from product design to end of life (EOL). Shyft’s secure, environmentally friendly IT asset disposition (ITAD) services offer sustainable practices and compliant capabilities — including data erasure and e-cycling — that address EOL to help preserve product value and close the gap on technology waste.

-

Shyft is globally operational with repair services in every region of the world, and our state-of-the-art facilities can support any technology repair program. We track and manage all product to the highest specifications and quality via unique identifiers such as serial number, part number and revision level. Leverage our infrastructure to reduce your overall operational costs while meeting your customers’ needs.

Why Shyft Depot Repair Services?

0 +

0 M+

$ 0 B

0 +

What Can Outsourcing Repair Services Do for Your Company?

Discover how companies like yours outsource repair services to accelerate business transformation.